VEHICULAR ULTRA LOW CARBON ENERGY SYSTEMS

Introduction to the Background And Current Situation

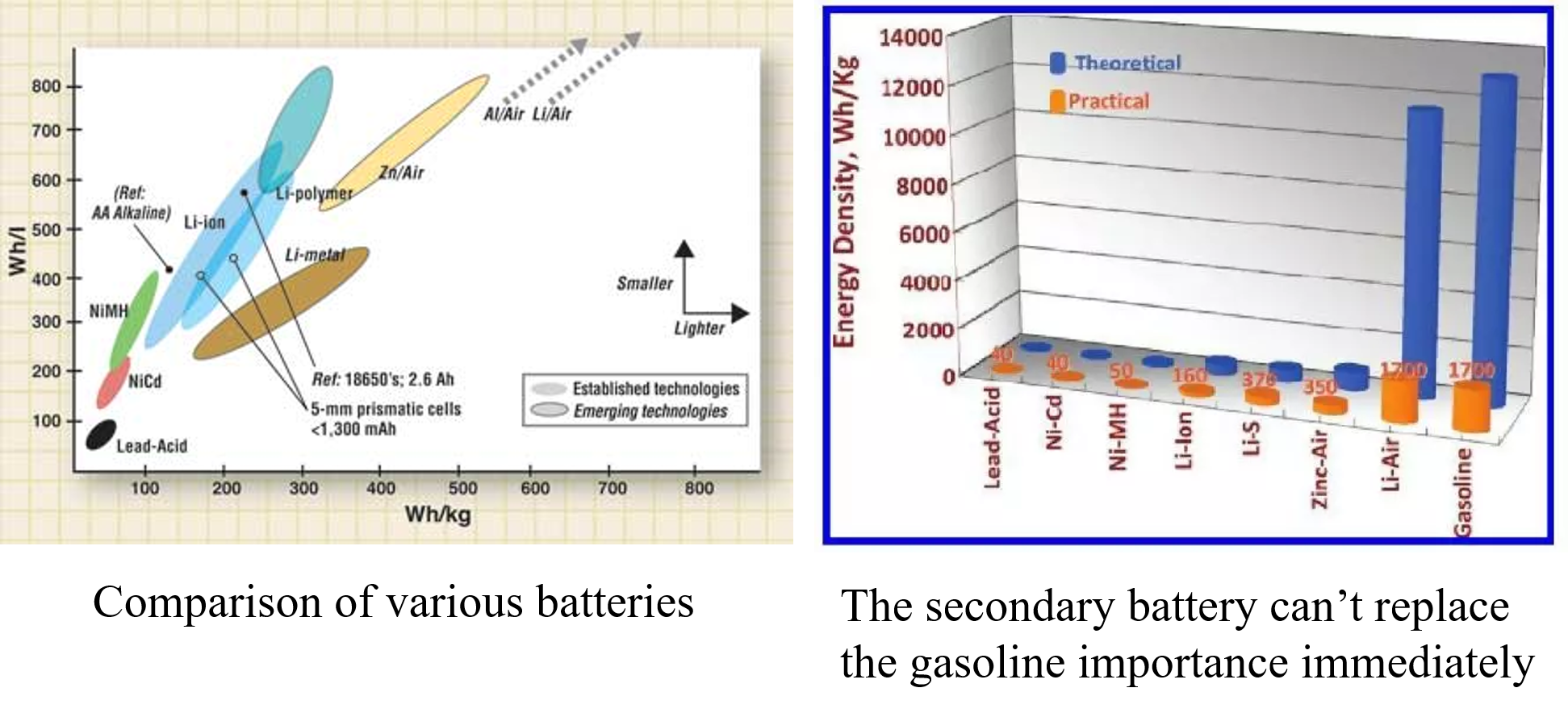

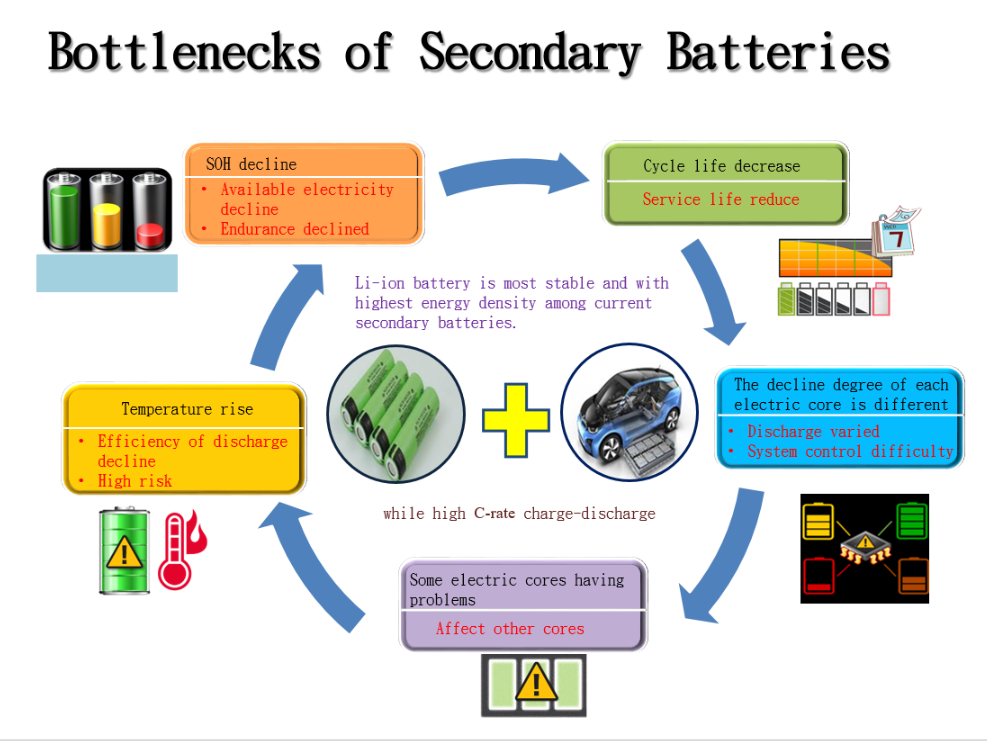

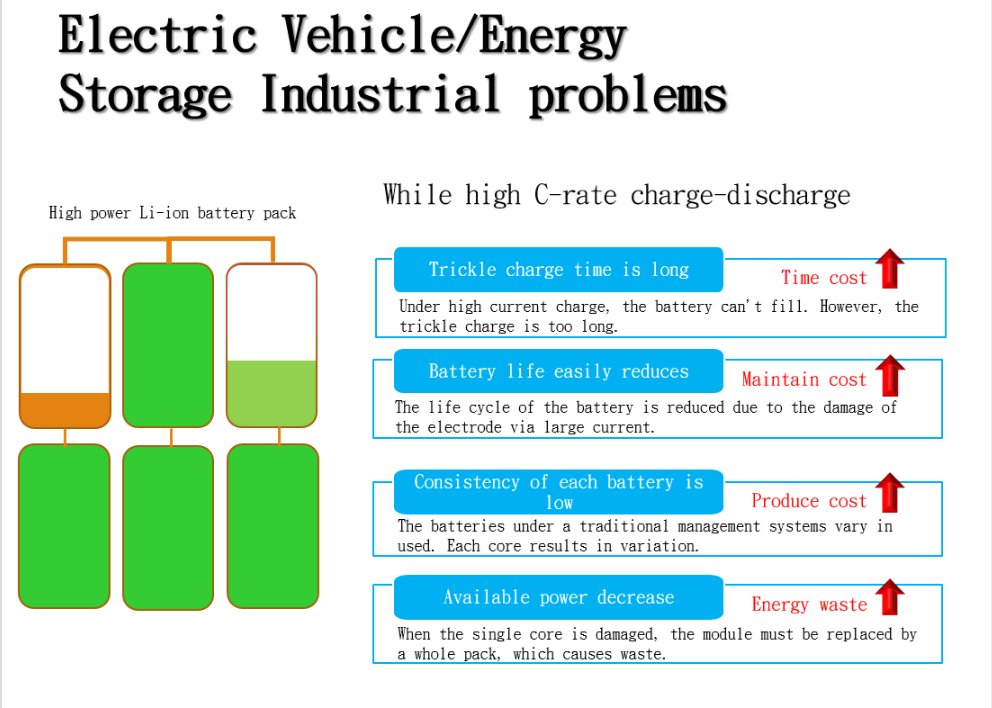

Bottlenecks of electric vehicle and energy storage

The situation in the industry of electric vehicle and green energy storage today:

2. High efficiency Internal Combustion Engine Technology

Recycle the composite pneumatic system of engine waste energy.

At present, the pure diesel engine power system, due to different operation conditions, ICE must always be in the state of acceleration or deceleration, but cannot stay under the best operating area of fuel efficiency. It not only causes the waste of energy but also the problem of emissions, which leads to low energy efficiency of the engine. The efficiency is usually about 15% . However, the exhaust gas of the ICE counts for more than 1/3 of the total energy released. If can be effectively recycled, it cannot only reduce the waste of energy but also the emission and pollution of the exhaust gas. In an overall view, the research on waste energy recovery in the academic circles is only using the heat exchanger waste gas to recover heat energy, but this system will completely recover the ICE wasted energy. The emission of exhaust energy and some of the heat discharged by the engine cooling system will be reused, the energy efficiency of the vehicle is estimated to be up to 33% .

The most notable application of gas energy is the air powered vehicle, which uses high 300 bar high pressure gas to store the energy and transfer the flow work into mechanical energy through a specially designed pneumatic engine, driving about 100 kilometers at a speed of 100 km/h, although the power system is in accordance with the concept of green environment. However, there are still bottlenecks such as insufficient power, poor endurance, no charging stations and high price.

Based on the above statement, a compound pneumatic system that can completely recover ICE waste energy, is proposed in this study. The system uses a (1) new active confluence device to recycle the exhaust gas from a high temperature and high pressure exhausted by an internal combustion engine, and through the mechanism with different pipe diameter to produce more power. This makes the exhaust energy of the internal combustion engine to be converted into effective mechanical energy, improving the engine thermal efficiency and reducing engine emission, fuel consumption and manufacturing cost. (2) The system provides a fixed load to the ICE by an air compressor, which can be maintained at the best operating point for low fuel consumption and low emission. This system will effectively reduce the emission of greenhouse gases. The design of the active confluence device with air compressor can make the thermal efficiency of the internal combustion engine up to 70%, and can effectively suppress the emission of exhaust gas and reduce the pollution to the environment.

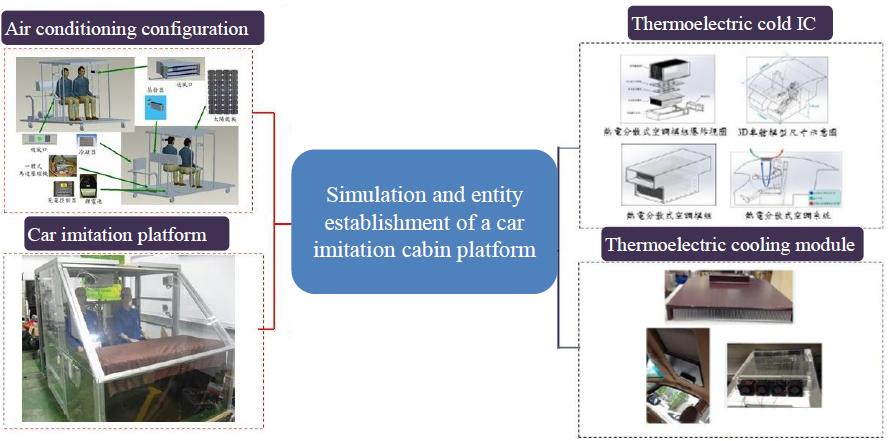

3. Energy saving technology and comfort of the car cabin